AS-Interface (Actuator Sensor Interface, AS-i) is an industrial networking solution (physical layer, data access method and protocol) used in PLC, DCS and PC-based automation systems. It is designed for connecting simple field I/O devices (e.g. Binary ON/OFF devices such as actuators, sensors, rotary encoders, analog inputs and outputs, push buttons, and valve position sensors) in discrete manufacturing and process applications using a single 2-conductor cable.

Sensor network system is becoming mandatory for most oil contractors to monitor the technology suppliers/vendors during every phase of the wireless system set-up and testing. II Overview of Wireless Sensor Network Emergence of the concept of multi-hop ad-hoc wireless networks, low-power electronics, low-power, short-range wireless communication radios, and intelligent sensors is considered the major technological enabler for. PA-II Dual Laser Air Quality Sensor. PurpleAir uses a new generation of laser particle counters that provide a cheap and accurate way to measure smoke, dust and other particulate air pollution. PA-II: Dual Laser Air Sensor. 1) Built in WiFi for logging to 'the cloud'.

AS-Interface is an 'open' technology supported by a multitude of automation equipment vendors. According to there are currently (2013) over 24 Million AS-Interface field devices installed globally, growing at about 2 million per year. AS-Interface is a networking alternative to the hard wiring of field devices. It can be used as a partner network for higher level fieldbus networks such as, Interbus and, for whom it offers a low-cost remote I/O solution.

It is used in automation applications, including conveyor control, packaging machines (e.g. Schubert's), process control valves, bottling plants, electrical distribution systems, airport baggage carousels, elevators, bottling lines and food production lines (e.g. AS-Interface provides a basis for in machinery safety/emergency stop applications. Safety devices communicating over AS-Interface follow all the normal AS-Interface data rules. The required level of data verification is provided by dynamic changes in the data. This technology is called Safety at Work and allows safety devices and standard, non-safe devices to be connected to the same network.

Using appropriate safe input hardware (e.g. Light curtains, e-stop buttons, and door interlock switches), AS-Interface can provide safety support up to SIL (Safety Integrity Level) 3 according to EN 62061, CAT 4 according to EN954-1 as well as Performance Level e (PL e) according to EN ISO 13849-1. The AS-Interface specification is managed by, a member funded non-profit organization located in Gelnhausen/Germany. Several international subsidiaries exist around the world. Contents. Overview AS-Interface is a system that requires four basic components:. Exactly one network master, in most cases in the form of a Gateway to a higher level industrial network or a PLC backplane card,.

A number of network slaves, in most cases input and output modules,. Exactly one power supply used to power the network slaves and enabling communication with the network master, and. The wiring infrastructure, in most cases accomplished using the yellow flat cable. Using these components an AS-Interface segment can be constructed. The underlying communication procedure is a, by which the master initiates data exchange with a slave and requires the slave to respond within its defined maximum time, making AS-Interface a networking solution. Conformance testing by an independent certification lab assures that certified products from all manufacturers will communicate on a given network.

Suppliers wishing to have their products conformance tested must contact. AS-Interface data exchanges are based on a Master-Call, where the data frame consists of a 5-bit device addresses, 4-bit data packets (e.g. Digital output information) and framing bits. The total length of the Master-Call is 14 bit. The resulting Slave-Response is 7 bit long, containing 4 bit of user information (e.g. The values of slaves inputs).

Voltage levels on the network range between 29,5. 31,6 V DC and data protection, in addition to the framing bits, is accomplished via coding, a highly symmetrical, floating layout with Alternating Pulse Modulation. The networks is 6 µs. Segment length is limited to 100 meters. Multiple segments can be combined to form longer networks.

In this case it is necessary to assure that every slave is only two repeaters 'away' from the network master. This is required due to the time delay introduced when a message packet transitions the repeater. Under certain conditions a so-called Terminator and/or Tuner can be used to extend the allowable segment length to 200 m or 300 m, respectively.

History AS-Interface was developed during the late 1980s and early 1990s by a group (consortium) of 11 companies mostly known for their offering of industrial non-contact sensing devices like,. Once development was completed the consortium was resolved and a member organization, was founded.

The first operational system was shown at the 1994 Hanover fair. Original specification (1994, Version 2.04) In its original form the network was capable of supporting up to 31 binary I/O devices/modules, where each device could exchange 4 bit of input and 4 bit of output data, resulting in a total of 124 inputs and 124 outputs on a single network. Important features like Automatic Single Node Replacement were already part of the system. The network update time is easily calculated by multiplying the number I/O nodes with the deterministic update time for each node (approximately 150 µs), for a maximum update time of 5 ms.

This simplified calculation does not include the Management Phase which is negligible for typical installations. It also does not include any communication retries. Enhancements (1998, Version 2.11) Following its introduction users quickly adopted AS-Interface, driving the demand for additional functionality and features. As a consequence, these demands were addressed with certain specification enhancements allowing the creation of analog input/output devices and increasing the number of possible binary I/O devices to 62. Diagnostics functionality was also enhanced by the creation of the Peripheral Fault Bit. In order to retain full forward and backward compatibility, the size of the data frame exchanged between the network master ( and ) was not increased.

Instead, one of the four output bits was used to select between the so-called A and B nodes. This enabled each of the 31 addresses to be used twice. The address space was increased to 1A to 31A plus 1B to 31B. As a consequence of using an output bit as the A/B selector, the fourth output bit was not available to the user and binary I/O nodes built to this profile offered a maximum of 4 inputs and 3 outputs, increasing the total amount of I/O on a single network to 248 inputs and 186 outputs. The maximum update time of a fully loaded network is 10 ms.

Additional capabilities (2005/2007, Version 3.0) By 2005 it became necessary to address additional user requirements. Also, the increased usage of Ethernet-based industrial protocols called for a low level solution that overcame the inherent shortcomings of Ethernet (e.g. Restricted topology, large data frame, costly usage of switches.) This specification addressed the users requirements by defining new communication profiles for binary and analog data plus the introduction of a serial data transmission profile. The following is an incomplete list of the new capabilities. Binary I/O nodes supporting A/B addressing with 4 inputs and 4 outputs.

Binary I/O nodes supporting A/B addressing with 8 inputs and 8 outputs. Configurable (8, 12 or 16 bit) fast analog channel. Full Duplex bit serial data channel With these new capabilities, AS-Interface becomes the ideal partner network for any of the currently available Ethernet-based industrial protocols. Gateways to EtherNet/IP TM, Modbus/TCP, and others are available.

Some controls experts have voiced the opinion that within the next 10 years networking solutions positioned between AS-Interface and Ethernet will not be used in any new installation. In a worst-case scenario, using 62 nodes with 4 inputs and 4 outputs each the update time is 10 ms for the inputs and 20 ms for the outputs. Components An AS-Interface network requires only a few basic components falling into the following general categories:. Scanners / Gateways (also called masters). Power supplies and repeaters.

Modules (also called slaves). Network cable, installation hardware and useful tool (infrastructure) Scanners and gateways The Scanner/Gateway performs two functions. With respect to the AS-Interface network it is a master, performing the data exchange with the modules and updating its internal I/O image. The functionality of the master is defined in the Master Profile of the AS-Interface specification. As part of specification version 3.0 the M4 Master Profile has been defined. Any given network can only have one Scanner/Gateway. With respect to a connected PLC/DCS or PC the Scanner/Gateway is a slave.

The AS-Interface community typically uses the word Gateway when the AS-Interface master connects to an upper-level network like, or any of the industrial Ethernet flavors. On the other hand, if it resides on the backplane of a PLC it is usually referred to as a Scanner. Since AS-Interface communication is based on the communication method, any network must have only one master at a time. Power supply Any AS-Interface segment must be powered.

This is typically accomplished by connecting an AS-Interface. These supplies have certain unique characteristics regarding internal circuitry and output voltage. Standard 24 V DC power supplies cannot be used to directly power a segment, 31.5 V DC must be used instead. The total length AS-Interface network cable in a single segment must be no more than 100 m. If the total network length must be longer, repeaters can be used. As the repeater galvanically isolates any two segments, a new power supply must be used on the far side of the repeater. A common misconception exists concerning the number of repeaters in a network.

It has been stated that the maximum length of an AS-Interface network can be 300 m, created by using two repeaters. This is not the case. What matters is not how many repeaters are using but rather how many repeaters any data packet, originating at a Scanner or Gateway, has to cross before reaching the I/O node. Due to the tight timing constraints defined each packet can at most travel across two repeaters before reaching an AS-Interface node.

This has the following consequences:. Linear networks with the Scanner/Gateway mounted at one end can be 300 m long. Linear network with 500 m length can be constructed when the Scanner/Gateway is mounted in the middle segment. Star shaped networks with virtually no length limitation are possible Modules This is by far the largest group of components and includes binary and analog I/O modules, stack lights, push buttons, sensors with integrated ASIC, valve control boxes, E-stops, light curtains; in general any device that can exchange data with the PLC. Each module on the network must have a unique address. For AS-Interface the address space ranges from 0 to 31, where 0 cannot be used, but is reserved for Automatic Single Node Replacement. Since adoption of specification 2.11 this address space is further divided into A and B extended addresses.

As a result, using a module designed to support this addressing mode, it is possible to have two modules at each address; one at the A half and one at the B half. 1A and 1B, 17A and 17B) The current specification Version 3.0 has added the ability to construct many new types of I/O combinations, including binary modules with 4 inputs and 4 outputs supporting A/B addressing. Network cable The vast majority of AS-Interface installations utilize the AS-Interface flat cable, defined as part of the AS-Interface specifications. A relatively small number of industries (e.g.

Valve control in process automation) use a round cable, mostly because it is easier to pull through conduit. While the shape of the cable does not matter (any other cable can be used) the electrical characteristics of the selected cable matters greatly.

To prevent problems due to improper cable, most professionals suggest the AS-Interface flat cable. This cable is designed to make use of a cable piercing technology. When an AS-Interface module is installed on the network, piercing needles penetrate the cable jacket and displace the internal copper strands without cutting them. This allows AS-Interface modules to be installed anywhere on the network without cutting and preparing (i.e.

Removing cable jacket, stripping insulation and possibly applying a ferule) the cable first. The result is a faster installation without the chance of inadvertent shorts between the leads. Here is a flat cable drawing There are several types of cables available.

Yellow cable is usually used to power AS-Interface modules and enable communication between the field devices and the scanner or Gateway. This cable is offered in several jacket materials to address specific applications needs. The AS-Interface black cable is typically used to supply modules with 24 V DC AUX power.

Wireless Sensor Networks Iit Kharagpur

No communication takes place on this cable. Similar to the yellow cable, the black cable is also produced using various jacket material to address the specific needs of the application. A red-jacketed cable has been defined but is virtually unused. Its intended use was in applications where AC power is supplied to the field nodes. The two leads inside the AS-Interface cable are brown (+ lead) and blue (− lead) independent of material makeup and outer jacket color. Designing a network An AS-Interface network is a collection of network segments.

There are very few rules that need to be satisfied when designing an AS-Interface network:. There can be no duplicate addresses on a network. Each segment must be 100 m or less in total cable length unless a Tuner is used, in which case the segment cable length must not exceed 200 m. Each network must master. Each segment must AS-Interface power supply.

When repeaters are used, a slave can not be more than 'two repeater transitions' from the master. The shape (i.e. Topology) of a segment is arbitrary (unrestricted) Using these basic rules it should be clear that. A linear network, with the master at one end of the network, can be 300 m long. A linear network, with the master 'in the middle' of the network, can be 500 m long In some applications longer networks are desirable (e.g. Process Automation applications). This is possible through the installation of and Tuners.

Terminator and tuner Terminators are fixed value devices that must be added at the physical end of a network and are designed to reduce signal reflections. In most cases Terminators will only work reliably if the segment is essentially linear. This is a significant limitation as most AS-Interface networks make extensive use of the fact that any arbitrary network topology can be used. A Tuner is used in much the same way as a Terminator (again segments have to be linear) but differs in its electrical characteristic.

A Tuner must, after connecting it to the segment, be activated (or tuned). During this process the Tuner actively varies the values of it internal termination components and determines the optimal settings for the segment, i.e. Those that minimize the number of network errors. Even though this optimization process is the strength of the Tuner and the sole reason for its ability to allow even longer networks, it is also its greatest disadvantage. While a Terminator allows the addition (or subtraction) of modules without additional work, a Tuner must be 're-tuned' whenever the network is changed (i.e. Removing/adding modules and adding/removing network cable.) When using Terminators and Tuners in conjunction with repeaters, the signal propagation time along the wire and across repeaters must be considered. Higher speed repeaters have been developed to address this issue.

Other components Passive taps, flat-to-round cable adapters, handheld addressing tools and many other accessories are designed to further assist in the installation of AS-Interface networks. References.

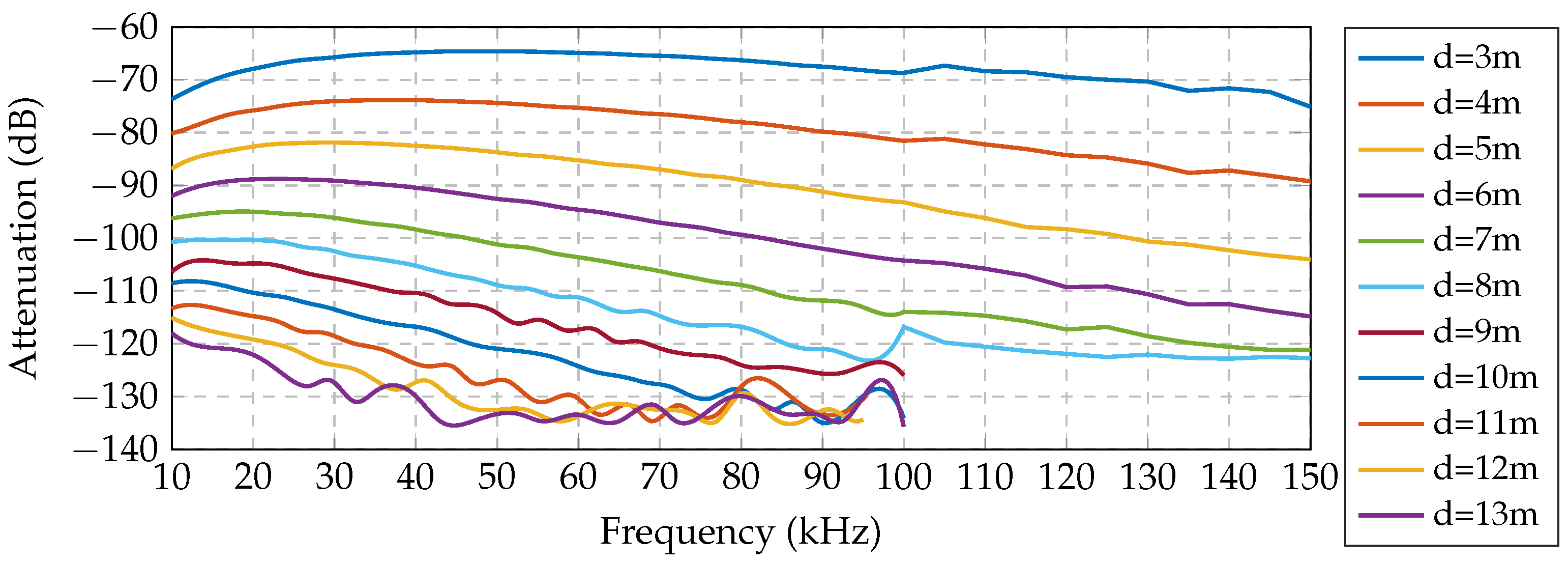

Ocean bottom sensor nodes are deemed to enable applications for oceanographic data collection, pollution monitoring, offshore exploration, disaster prevention, assisted navigation and tactical surveillance applications. Multiple Unmanned or Autonomous Underwater Vehicles (UUVs, AUVs), equipped with underwater sensors, will also find application in exploration of natural undersea resources and gathering of scientific data in collaborative monitoring missions. To make these applications viable, there is a need to enable underwater communications among underwater devices. Underwater sensor nodes and vehicles must possess self-configuration capabilities, i.e., they must be able to coordinate their operation by exchanging configuration, location and movement information, and to relay monitored data to an onshore station. Wireless underwater acoustic networking is the enabling technology for these applications. UnderWater Acoustic Sensor Networks (UW-ASN) consist of a variable number of sensors and vehicles that are deployed to perform collaborative monitoring tasks over a given area. To achieve this objective, sensors and vehicles self-organize in an autonomous network which can adapt to the characteristics of the ocean environment.

Underwater networking is a rather unexplored area althoughunderwater communications have been experimented since World War II, when, in 1945, an underwater telephone was developed in the United States to communicate with submarines. Acoustic communications are the typical physical layer technology in underwater networks. In fact, radio waves propagate at long distances through conductive sea water only at extra low frequencies (30-300 Hz), which require large antennae and high transmission power. Optical waves do not suffer from such high attenuation but are affected by scattering. Moreover, transmission of optical signals requires high precision in pointing the narrow laser beams. Thus, links in underwater networks are based on acoustic wireless communications.

The traditional approach for ocean-bottom or ocean column monitoring is to deploy underwater sensors that record data during the monitoring mission, and then recover the instruments. This approach has the following disadvantages:. Real time monitoring is not possible. This is critical especially in surveillance or in environmental monitoring applications such as seismic monitoring. The recorded data cannot be accessed until the instruments are recovered, which may happen several months after the beginning of the monitoring mission.

No interaction is possible between onshore control systems and the monitoring instruments. This impedes any adaptive tuning of the instruments, nor is it possible to reconfigure the system after particular events occur.

If failures or misconfigurations occur, it may not be possible to detect them before the instruments are recovered. This can easily lead to the complete failure of a monitoring mission. The amount of data that can be recorded during the monitoring mission by every sensor is limited by the capacity of the onboard storage devices (memories, hard disks, etc.). Therefore, there is a need to deploy underwater networks that will enable real time monitoring of selected ocean areas, remote configuration and interaction with onshore human operators. This can be obtained by connecting underwater instruments by means of wireless links based on acoustic communication.

Many researchers are currently engaged in developing networking solutions for terrestrial wireless ad hoc and sensor networks. Although there exist many recently developed network protocols for wireless sensor networks, the unique characteristics of the underwater acoustic communication channel, such as limited bandwidth capacity and variable delays, require for very efficient and reliable new data communication protocols. Major challenges in the design of underwater acoustic networks are:.

Battery power is limited and usually batteries can not be recharged, also because solar energy cannot be exploited;. The available bandwidth is severely limited;.

Channel characteristics, including long and variable propagation delays, multi-path and fading problems;. High bit error rates;. Underwater sensors are prone to failures because of fouling, corrosion, etc.

Point measurements in upper water column 10 and 25 mi off Moss Landing. Drift buoy: Path followed by surface currents.